| Sign In | Join Free | My uabig.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My uabig.com |

|

Brand Name : Laurel

Model Number : Laurel-02-02

Certification : ISO9001

Place of Origin : Zibo, China

MOQ : 1 pcs

Price : USD 2-10 /pcs

Payment Terms : T/T;L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 1000 ton/month

Delivery Time : 10~15 days

Packaging Details : Carton box or pallets

Product name : Ceramc fiber modules

Shape : Rectangle

Feature : Heat insulation and sound absorption

Usage : linings, furnaces and kilns etc

Temperature Range : 1260℃ to 1430℃

Color : Pure white

Length : 300 or customized

Density : 160-300 kg/m3

Certificate : CE

Raw material : Quartz sand ,aluminium oxide

Feature 1 : Good insulation performance

Feature 2 : Low thermal conductivity

Application : Refractory insulation

Fiber diameter : 3-5 um

Working temperature : 1000-1350

Grade : HA (High Aluminum), COM (Common), HP (High Pure)

Chemical composition : AL2O3+SIO2

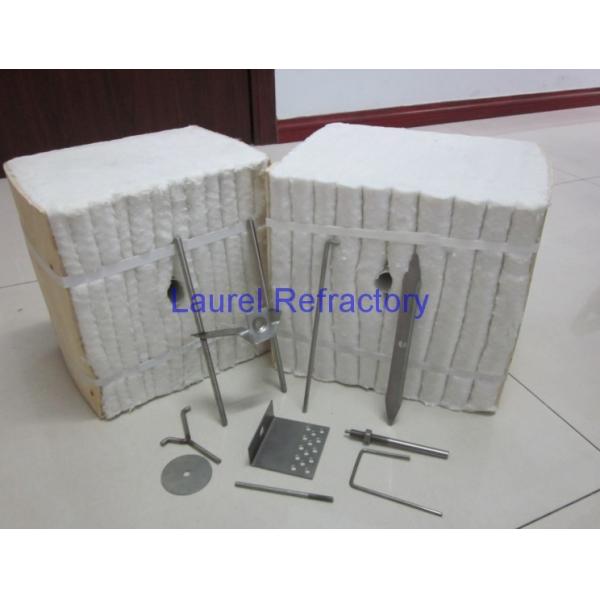

High temperature pipe insulation ceramic fiber modules for boilers and fire door

We are a specialized manufacturer of refractory and heat insulation with more than 10 years’ history. Now it has 20,000 sqm floor area and can produce 20,000 tons of more than 10 kinds of medium and top grade refractory and heat insulation material annually. Both Research & Development Center for technology and Testing center for chemical and physical properties are established.

Laurel modules have the highest insulating value achievable in a ceramic fiber. Each module is a continuous folded blanket under compression. The individual sheet is allowed. Module linings prevent heat loss, increasing the furnace productivity and reducing maintenance costs.

Ceramic Fiber Module

which all can be processed mechanically,and with the advantage of smoothly surface and ant-erode,no fiber rupture , Products are divided into: common , high pure, high aluminum , zirconium type aluminum silicate ceramic fiber module.

| Item | Standard | H Pure | Zirconium |

| AL2O3(%) | ≥44 | ≥45 | ≥34 |

| Sio2(%) | ≥52 | ≥54 | ≥50 |

| Fe2O3+Tio2(%) | ≤1.0 | ≤0.5 | ≤0.5 |

| ZrO2(%) | - | - | ≥15 |

| Classification Temperature (℃) | 1260 | 1260 | 1430 |

| Working Temperature (℃) | 1050 | 1100 | 1350 |

| Density (kg/m3) | 220 | 220 | 220 |

| linear shrinkage after heating(%) @24 hours | ≤2.5(1000°C) | ≤2.5(1100°C) | ≤3.5(1350°C) |

| Thermal Conductivity(w/m.k) @400°C | 0.090 | 0.101 | 0.118 |

The most advanced full auto equipment and strictly QC control system could guarantee quality to meet the requirements of the local and international markets ,and we are famouse for the safe package and prompt delivery.

1. Competitive Price. Make the products competitive in your market.

2. Abundant Experience. Prevent cracks and twist in bricks.

3. Different Moulds. Save mould fees for you.

4. Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5. Strict Quality Control. Meet clients' quality requirement.

6. Safty packing,prompt delivery time,and excellent after-sales services.

7. Large stocks. Guarantee prompt delivery.

8. Professional Packing. Avoid damage and secure the goods in transportation.

|

|

High Temperature Pipe Refractory Fireproof Insulation Ceramic Fiber Wool Modules For Boilers And Fire Door Images |